Product name:

Keeping efficient and friendly customer service as the top concern, provides ultimate flexibility in fulfilling each & every customer requirement irrespective of the size of order. Most of our clients are doing business with us since years, which indicates higher levels of customer satisfaction. We always welcome any queries or suggesions from our clients to improve the services and hence to serve them better.

Q1:Accepted delivery terms

A1:EXW, FOB, CFR, CIF, FCA, FSA, CPT, CIP, DAT, DAP, DDP, DDU

Q2:Accepted Payment Types

A2:T/T, L/C

Q3:What is your delivery time ?

A3:8000 tons of inventory guarantee immediate delivery, Non-stock products, delivery within 5-7 days.

Q4:Accepted payment currencies

A4:CNY, USD, EUR, JPY, CAD, AUD, HKD, GBP, CHF

Q5:What standard steel can you provide?

A5:We can provide various standards, such as: AISI, ASTM, ANSI, ASME, UNS, SAE, DIN, EN, GB, JIS, etc

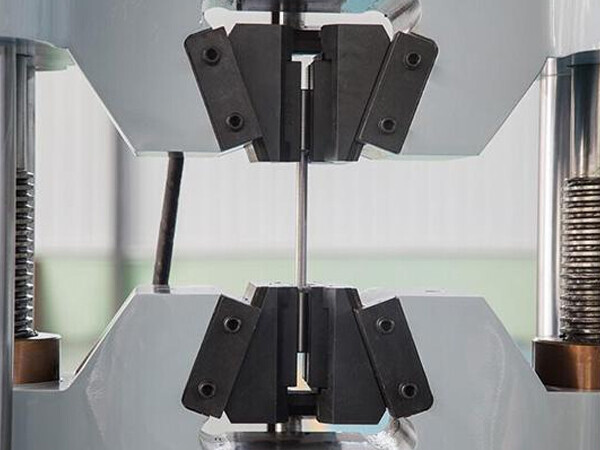

Q6:How do you guarantee the product quality?

A6:CE, ISO certificate, supporting any third party inspection. A pre-production sample before mass production, final Inspection before shipment.

Related Products

Please give us a message

Oriental Deno International Trade